Composites have been used for space applications due to their high performance properties. However, the environmental conditions experienced during space exposure lead to severe structural damage.

Blog by Mayra Rivera Lopez, PhD Researcher, Bristol Composites Institute (ACCIS) Advanced Composites Collaboration for Innovation and Science, Department of Aerospace Engineering, University of Bristol

This project was awarded seed corn funding from the new Jean Golding Institute Post Graduate Researchers seed corn award scheme 2020.

Project aims

- Select current ultra-thin carbon fibre reinforced composites (CFRP) based on thermoset resins used to manufacture space deployable structures. The presence of nanofillers on these resins will be considered for some samples.

- Set the selected CFRPs samples in a plasma generator chamber to simulate space exposure at a low Earth orbit for up to twelve months.

- Perform 3D surface topography analysis by using the Alicona Infinite focus microscope on each sample. These tests will identify any surface imperfection on the composites, leading to a deterioration of their mechanical properties.

- The overall void volume will be analysed and identify significant resin modifications which could act as a focal point for crack propagation or radiation damage.

- Collect infrared analysis data from these composites before and after being exposed to plasma conditions (available from previous experiments at the University of Bristol).

- Create a correlation between the chemical structure of the resins obtained from the infrared data and the voids presence.

- Create a database to predetermine the best thermoset overall performance for space structures applications and establish how to optimise it.

Results

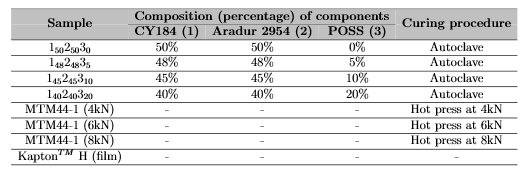

Materials Selection and Atomic Oxygen Exposure Details

Two different epoxy composites were selected to be analysed, including CY 184, Aradur 2954 and MTM44-1 materials. EP0409 Glycidyl POSS nanofillers at different contents (0, 5, 10, 15, and 20 wt%) were applied to these. The convention (1x2y3z) was selected where the subscripts display the content of each component. Moreover, two curing techniques were applied, the use of autoclave and compression plates. Table 1 displays the composition and manufacturing details of the laminates.

A JLS Designs Plasmatherm 550–570 radio frequency plasma generator was used to expose the samples to Atomic Oxygen (AO). A frequency of 150 W, constant pressure of 100 Pa and a constant O2 flow of 0.3 NL/min were applied to simulate space conditions for an equivalent of twelve months.

Surface Roughness Analysis

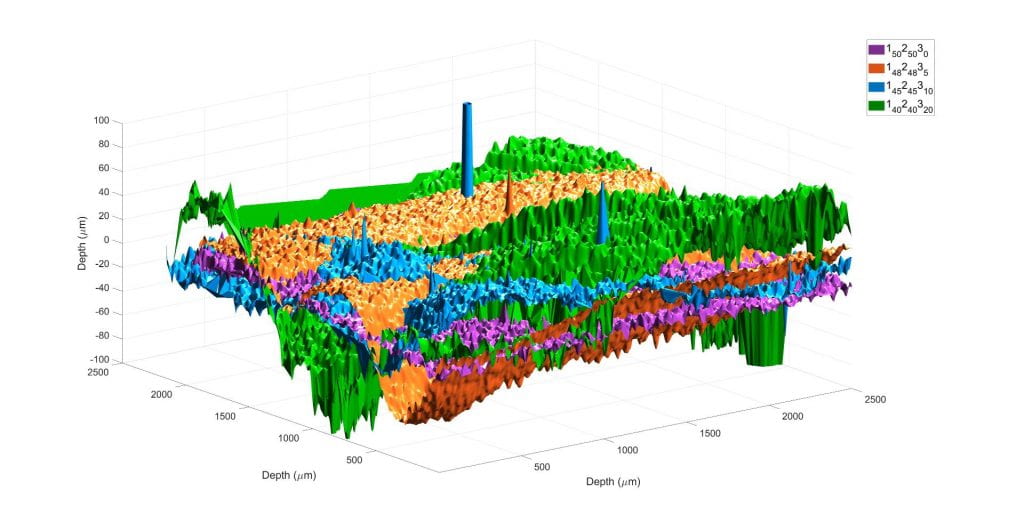

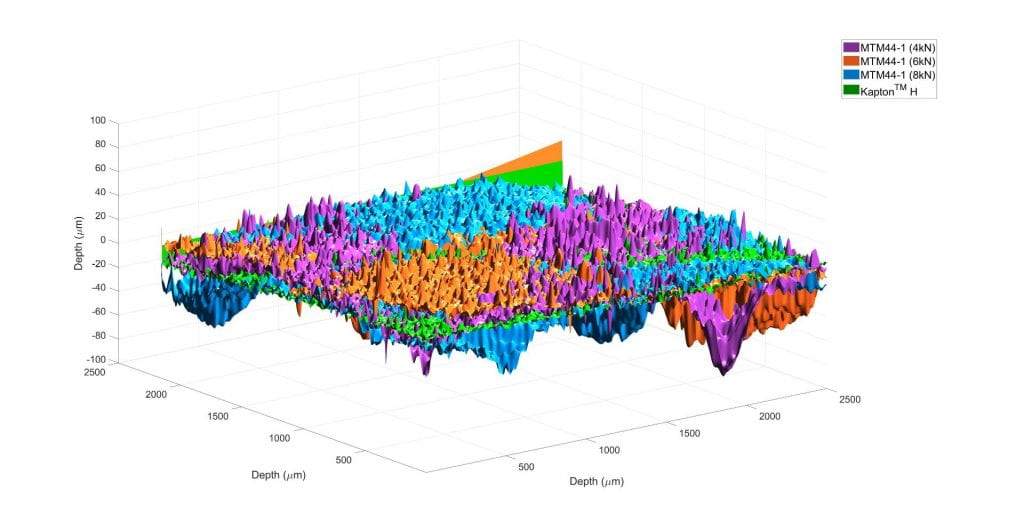

The 3D Surface topography images were obtained from scanned composite areas of 2.5mm × 2.5mm after AO exposure. An Alicona Infinite Focus instrument with a 5× objective was used to characterise the samples. The overall void volume was calculated on Matlab by using the 3D dataset files obtained for each sample and an average depth 2D threshold of each sample. On Figure 1, the composites depressions are observed due to the resin degradation after exposure. On Table 2 the overall void content for each sample is presented. The laminates containing POSS(3) have a smoother pattern (except 180280320) compared to the laminates with only MTM44-1 (including 4kN, 6kN and 8kN), as a silica-based coating was created, protecting the fibres from being exposed.

Figure 1: 3D voidage comparison of the cured ultra-thin composites and KaptonTMH after twelvemonths of AO exposure

Fourier Transform Infrared (FTIR) Spectroscopy

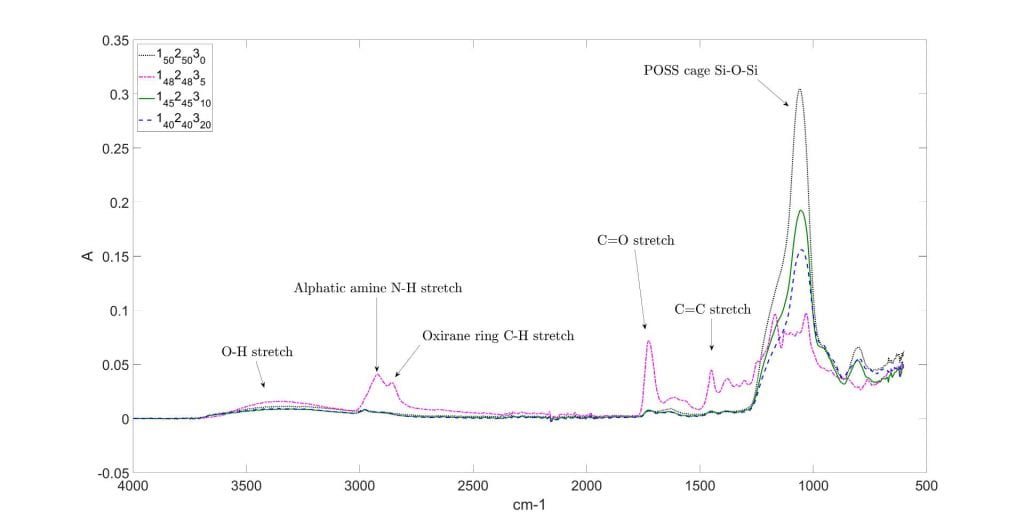

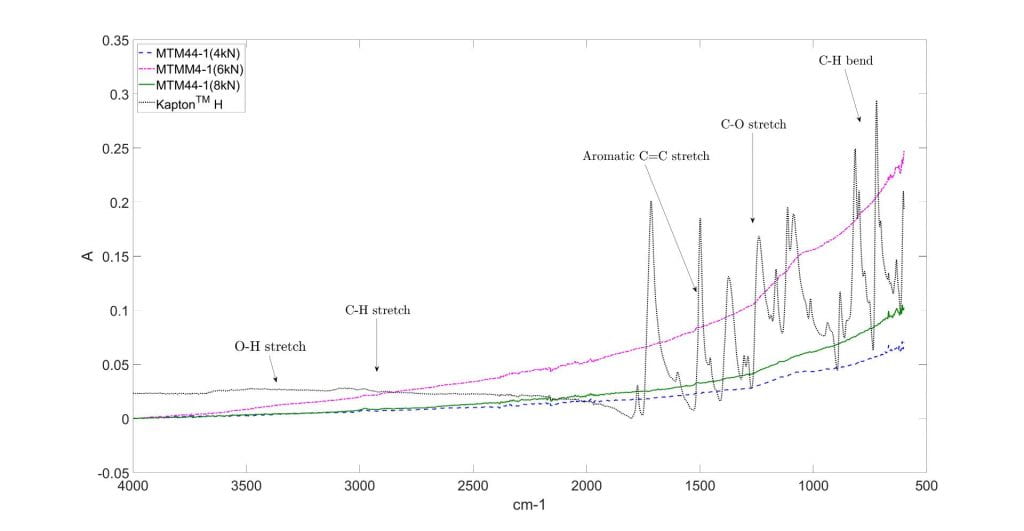

A Perkin Elmer Fourier-transform infrared (FTIR) spectrometer was used to analyse the Attenuated Total Reflectance (ATR) of the surface spectroscopy. Fifteen scans were performed per sample over a spectral range of 650–4000 cm−1. Figure 2a displays the absorption bands of the composites with POSS nanofiller. Significant peaks at the aliphatic amine N-H stretching region (2800-3000cm−1), as well as an intense band around 1100 cm−1 were observed. This is related as after AO samples exposure, the epoxy rings were opening due to the reaction with the POSS and diamine molecules, leading to the construction of hydroxyl groups. Figure 2b the laminates without nanofillers were presented, including KaptonTM H, with a significant change on the oxirane ring due to C-H stretching vibrations.

Figure 2: Infrared spectra of the cured epoxy ultra-thin composites and KaptonTM H after twelve months of AO exposure

Correlation

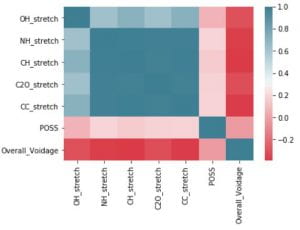

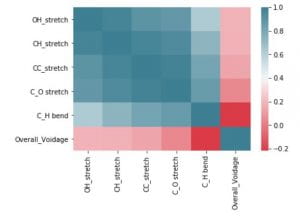

A standard correlation, following Pearson’s method applied on JupyterLab was followed based on the dataset obtained from each sample after exposing them on an interval of two months, until a total of twelve months was achieved. Figure 3 shows the relationship between each selected infrared band presented on Fig 2 and the voids content of each composite. The overall voidage for laminates with nanofillers (Fig.3a) relies more on the change of the POSS band (1100cm−1) due to coating creation. However, this value is less dependent on the C-H stretching vibrations (2850cm−1). For MTM44-1 composites (Fig.3b), C-H stretch band presented the most positive correlation with the overall voidage and the most negative is with the C-H bend region (800cm−1). It was observed that mostly all the bands were directly related to each other after each exposure.

Figure 3: Correlation between selected infrared bands and overall voidage content

Future work

For future work, the dataset size established during this project could increase, by selecting a wider range of thermosets or any other types of materials applied for space structures. This will allow the selection of the material accordingly to the structure performance require. Moreover, further tests, such as Thermogravimetric Analysis (TGA), Dynamic Scanning Analysis (DSC) and Nuclear Magnetic Resonance (NMR) could be applied to achieve a more detailed characterisation of the resins. The mechanical properties of the samples could also be analysed based on three-point bending test and tensile testing to observe the stiffness, strength and toughness properties and identify the advantages or disadvantages of the nanofiller percentages on the structures. Finally, this analysis could also be applied to different areas,such as the aeronautical, maritime and civil sectors, as well as medical engineering areas to select the best resin composite depending on the application required.

Contact details

mayra.riveralopez@bristol.ac.uk

Bristol Composites Institute (ACCIS), Advanced Composites Collaboration for Innovation and Science, Department of Aerospace Engineering, University of Bristol BS8 1TR

Jean Golding Institute Seed Corn Funding Scheme

The Jean Golding Institute run an annual seed corn funding scheme and have supported many interdisciplinary projects. Our next round of funding will be in Autumn 2020. Find out more about our Funding opportunities